Drill Press Swaging Tool Operating Instructions

1) Install tri-roller swaging tool (1) into drill press chuck or vertical milling machine.

2) Adjust spindle speed - recommend approximately 60-100 rpm for initial pieces (Note: This can later be increased up to

250 rpm, once operator proficiency has been developed).

3) Install bearing into housing (4) per the drawing specification.

Operating instructions

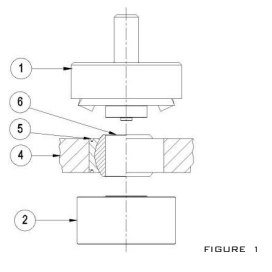

1) Position part (sub-assembly – bearing & housing) on the flat surfaced locating fixture (primary) (2), FIG. 1 in bearing

bore.

2) With part resting on locating fixture slowly lower the spindle — ensuring roller fixture bushing is piloted into the

bearing bore (6).

3) Start spindle and apply light pressure for initial revolutions to allow rollers to center in bearing groove (5).

4) Repeat 1-2 times applying normal arm pressure and maintain swaging tool engagement for approximately 5 seconds.

5) Release pressure and withdraw tool from bearing/housing sub-assembly.

6) Inspect swage per the requirements of the drawing or swaging specification.

7) Repeat steps 4 through 6 until swage is complete.

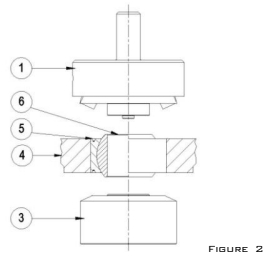

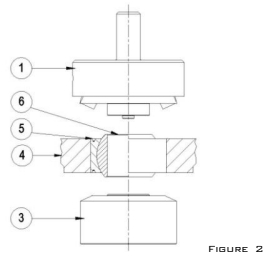

8) Turn sub-assembly over and repeat steps 1 thru 7 to complete swaging on opposite side except use angled (conical)

surfaced locating fixture (secondary) (3), FIG. 2 for this operation.

Note:

Do not grease rollers or bearing lip - Use light machine oil only.

Clean debris from tool rollers frequently using an air gun.

If application requires installation with sealant or primer, remove excess from bearing groove prior to swaging.

Additional Tools For This Bearing

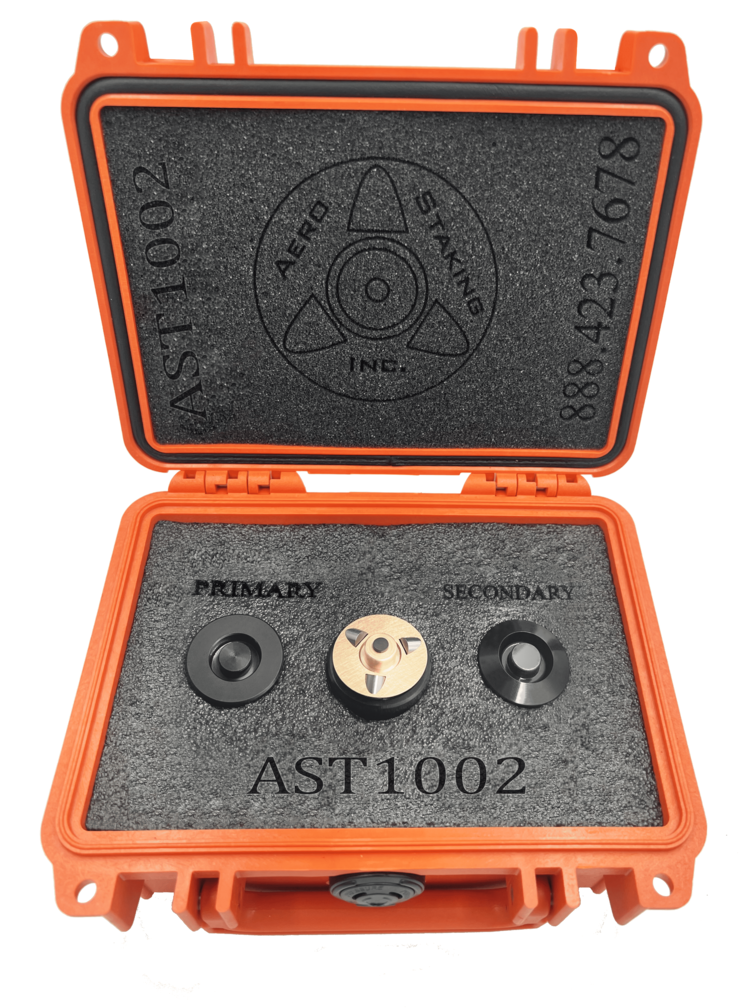

AST1002 Portable Tri Roller Swager

Original Aero Staking Bearing Swaging Tool

This Aero Staking bearing swaging tool is engineered for high-precision bearing installation and retention in aerospace and industrial applications. Ideal for production environments, it ensures durable and reliable results when installing MS14103-4 bearings.

Tool Specifications:

-

For Bearing Number: MS14103-4

-

Bearing Groove Pitch Diameter (PD): 0.563

-

Bearing Inner Diameter (ID): 0.250

-

Standard Outer Envelope: Diameter 1.375” OD

Precision Swaging with Aerospace-Grade Quality

This bearing swaging tool is manufactured using aerospace-quality treated and coated tool steel for long-lasting durability and consistent performance. It includes:

-

Flat-Surfaced Locating Fixture (Primary): For the initial swage

-

Angled (Conical) Locating Fixture (Secondary): For the final swage

-

Roller Swaging Fixture (Head): Ensures accurate and smooth bearing retention

Ideal for Batch Production & Bearing Retention

The Original Aero Staking swaging tool is the preferred choice for both small-scale and high-volume production runs. It’s designed for accurate bearing retention, bearing replacement, and bearing installation—ensuring aerospace-grade precision in every cycle.

Whether you’re working on one-off repair jobs or ongoing manufacturing, this bearing swaging tool performs with reliability and repeatable accuracy.

Compatible with Common Shop Equipment

This drill press swaging tool integrates seamlessly with a variety of equipment, including:

-

Standard knee mills

-

Drill presses

-

Manual milling machines

-

CNC milling machines

The tool features a ½” diameter shank, making it easy to fit into your current production setup without modification.

Why Choose Aero Staking Bearing Swaging Tools?

Aero Staking is trusted globally for producing premium tri roller swagers and bearing swaging tools tailored to the demanding needs of aerospace maintenance, installation, and manufacturing.

AST1002 Portable Tri Roller Swager

Original Aero Staking Bearing Swaging Tool

This Aero Staking bearing swaging tool is engineered for high-precision bearing installation and retention in aerospace and industrial applications. Ideal for production environments, it ensures durable and reliable results when installing MS14103-4 bearings.

Tool Specifications:

-

For Bearing Number: MS14103-4

-

Bearing Groove Pitch Diameter (PD): 0.563

-

Bearing Inner Diameter (ID): 0.250

-

Standard Outer Envelope: Diameter 1.375” OD

Precision Swaging with Aerospace-Grade Quality

This bearing swaging tool is manufactured using aerospace-quality treated and coated tool steel for long-lasting durability and consistent performance. It includes:

-

Flat-Surfaced Locating Fixture (Primary): For the initial swage

-

Angled (Conical) Locating Fixture (Secondary): For the final swage

-

Roller Swaging Fixture (Head): Ensures accurate and smooth bearing retention

Ideal for Batch Production & Bearing Retention

The Original Aero Staking swaging tool is the preferred choice for both small-scale and high-volume production runs. It’s designed for accurate bearing retention, bearing replacement, and bearing installation—ensuring aerospace-grade precision in every cycle.

Whether you’re working on one-off repair jobs or ongoing manufacturing, this bearing swaging tool performs with reliability and repeatable accuracy.

Compatible with Common Shop Equipment

This drill press swaging tool integrates seamlessly with a variety of equipment, including:

-

Standard knee mills

-

Drill presses

-

Manual milling machines

-

CNC milling machines

The tool features a ½” diameter shank, making it easy to fit into your current production setup without modification.

Why Choose Aero Staking Bearing Swaging Tools?

Aero Staking is trusted globally for producing premium tri roller swagers and bearing swaging tools tailored to the demanding needs of aerospace maintenance, installation, and manufacturing.

Drill Press Swaging Tool Operating Instructions

1) Install tri-roller swaging tool (1) into drill press chuck or vertical milling machine.

2) Adjust spindle speed - recommend approximately 60-100 rpm for initial pieces (Note: This can later be increased up to

250 rpm, once operator proficiency has been developed).

3) Install bearing into housing (4) per the drawing specification.

Operating instructions

1) Position part (sub-assembly – bearing & housing) on the flat surfaced locating fixture (primary) (2), FIG. 1 in bearing

bore.

2) With part resting on locating fixture slowly lower the spindle — ensuring roller fixture bushing is piloted into the

bearing bore (6).

3) Start spindle and apply light pressure for initial revolutions to allow rollers to center in bearing groove (5).

4) Repeat 1-2 times applying normal arm pressure and maintain swaging tool engagement for approximately 5 seconds.

5) Release pressure and withdraw tool from bearing/housing sub-assembly.

6) Inspect swage per the requirements of the drawing or swaging specification.

7) Repeat steps 4 through 6 until swage is complete.

8) Turn sub-assembly over and repeat steps 1 thru 7 to complete swaging on opposite side except use angled (conical)

surfaced locating fixture (secondary) (3), FIG. 2 for this operation.

Note:

Do not grease rollers or bearing lip - Use light machine oil only.

Clean debris from tool rollers frequently using an air gun.

If application requires installation with sealant or primer, remove excess from bearing groove prior to swaging.

Additional Tools For This Bearing

Related Tools