Drill Press Swaging Tool Operating Instructions

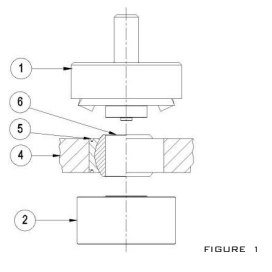

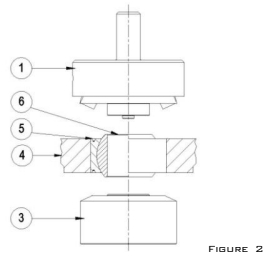

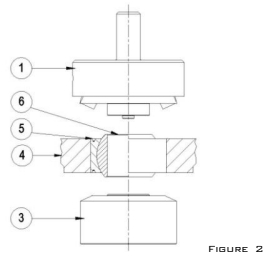

1) Install tri-roller swaging tool (1) into drill press chuck or vertical milling machine.

2) Adjust spindle speed - recommend approximately 60-100 rpm for initial pieces (Note: This can later be increased up to 250 rpm, once operator proficiency has been developed).

3) Install bearing into housing (4) per the drawing specification.

Operating instructions

Additional Tools For This Bearing

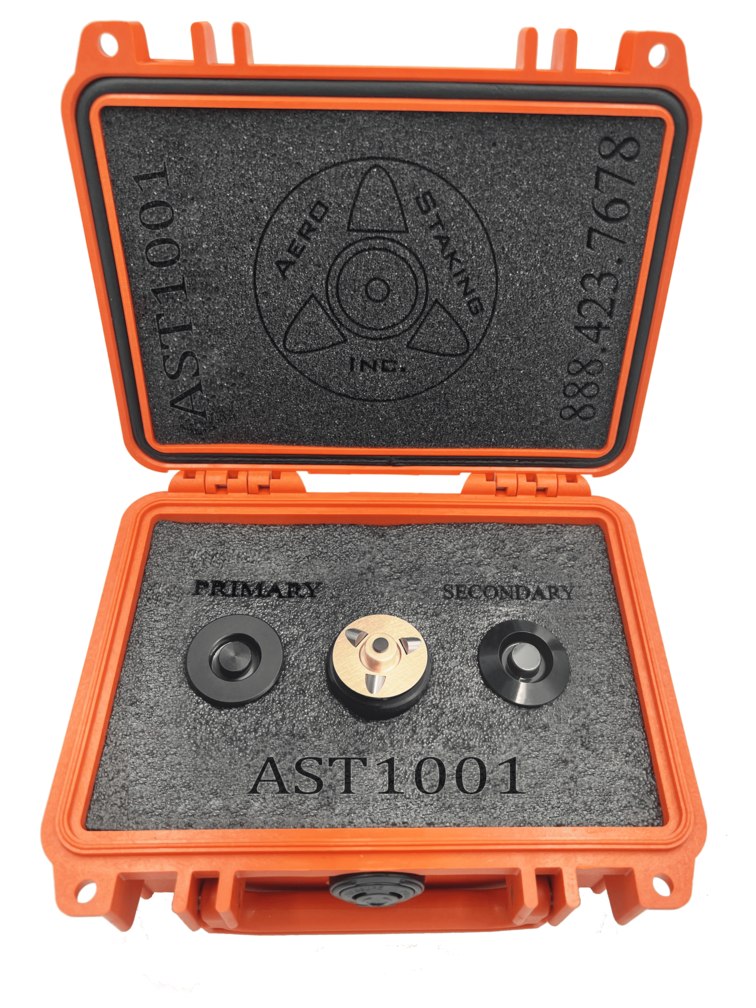

AST1001 Drill Press Tri Roller Swager

Original Aero Staking Bearing Swaging Tool

For Bearing Number: MS14103-3

Bearing Groove Pitch Diameter (PD): .563

Bearing Inner Diameter (ID): .1900

Standard Outer Envelope of the Tool: Dia 1.375” OD.

Description of the Tool:

The Drill Press Swaging Tool is made of Aerospace Quality, treated, and coated tool steel; it consists of the following:

- The flat-surfaced locating fixture (primary) – used for the first swage

- Angled (conical) surfaced locating fixture (secondary) – used for the second swage

- Roller Swaging Fixture (head)

This tool is used primarily for small and large batch production, bearing retention, installation, and bearing replacement operations.

Equipment Required:

- Standard knee mill, drill press, manual or CNC milling machine tool features ½ Dia shank

AST1001 Drill Press Tri Roller Swager

Original Aero Staking Bearing Swaging Tool

For Bearing Number: MS14103-3

Bearing Groove Pitch Diameter (PD): .563

Bearing Inner Diameter (ID): .1900

Standard Outer Envelope of the Tool: Dia 1.375” OD.

Description of the Tool:

The Drill Press Swaging Tool is made of Aerospace Quality, treated, and coated tool steel; it consists of the following:

- The flat-surfaced locating fixture (primary) – used for the first swage

- Angled (conical) surfaced locating fixture (secondary) – used for the second swage

- Roller Swaging Fixture (head)

This tool is used primarily for small and large batch production, bearing retention, installation, and bearing replacement operations.

Equipment Required:

- Standard knee mill, drill press, manual or CNC milling machine tool features ½ Dia shank

Drill Press Swaging Tool Operating Instructions

1) Install tri-roller swaging tool (1) into drill press chuck or vertical milling machine.

2) Adjust spindle speed - recommend approximately 60-100 rpm for initial pieces (Note: This can later be increased up to 250 rpm, once operator proficiency has been developed).

3) Install bearing into housing (4) per the drawing specification.

Operating instructions

Additional Tools For This Bearing

Related Tools